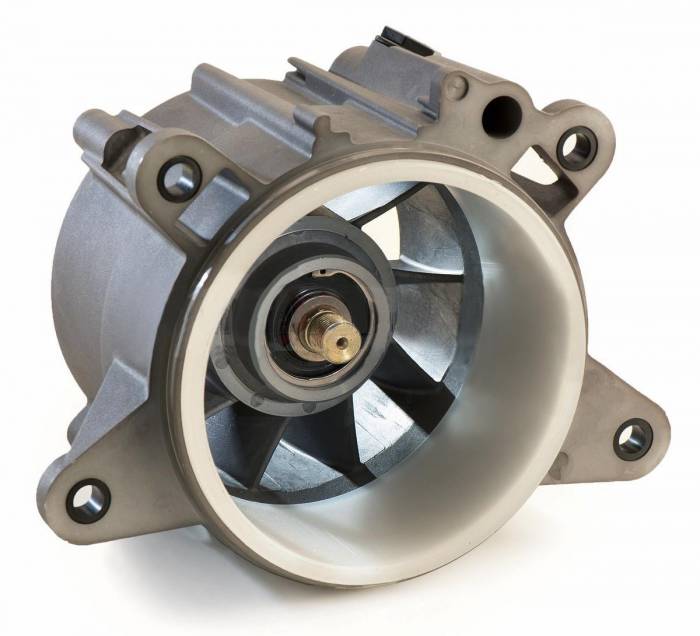

All modern jet skis use an axial jet pump – a tube and nozzle setup that sprays water out with great force.

The jet ski pump consists of a housing, wear ring and impeller. The wear ring can be either plastic or stainless steel, depending on the make of your jet ski.

The jet ski impeller fits tightly and spins inside of the wear ring, which sits inside of the housing.

The jet ski wear ring and the impeller are the two parts that generally wear or are damaged. And are generally both replaced at the same time.

IS MY WEAR RING AND/OR IMPELLER BAD

If either part is worn or damaged it should be fairly obvious.

- The blades are bent or chipped.

- General wear and use. Too large a gap between the impeller and wear ring, scraping or cut grooves in the wear ring. These can increase the size of the wear ring and reduce the effectiveness of the impeller.

UNIVERSAL WEAR TEST

The quick and easy rule of thumb is the business card test. The gap between the impeller and wear ring can be up to one business card in width. If you can slide two business cards between the two it is past being “good”.

Corrosion on either the impeller or wear ring. This will decrease the size of the wear ring and can cause the impeller to lock up.

Damage, wear or corrosion will result in the impeller not spinning smoothly within the wear ring or even to not spin at all.

NOTE:

Jet pumps, by design, are fairly inefficient.

On a boat, a good propeller may run at 90% efficiency. This means if the boat is going 55mph, the water pushing off the propeller is about 60mph.

If a jet ski is running 60mph, the water shooting out the back is well over 100mph.

If the wear ring is worn and the gap between wear ring and impeller is too large, water will still shoot out of the back at over 100mph, but the jet ski may only run at 40mph.

Impeller Tools And Seals Charts below: