A key component to complete the re-building of a carburetor is the pop-off test.

The pop-off is a CRITICAL component of the carb tuning mix. Incorrect pop-off can cause severe performance issues, and engine damage.

What is Pop-Off?

Pop-off is the fuel pressure at which the needle releases from the seat and allows fuel to flow into the carb. The needle and seat control the rate of fuel flow, and is equivalent to FLOAT HEIGHT on a conventional carb.

How do I adjust pop-off?

The truth is YOU DON’T “ADJUST” pop-off. You “CHECK” the pop-off.

The Magic of the Pop-Off Test.

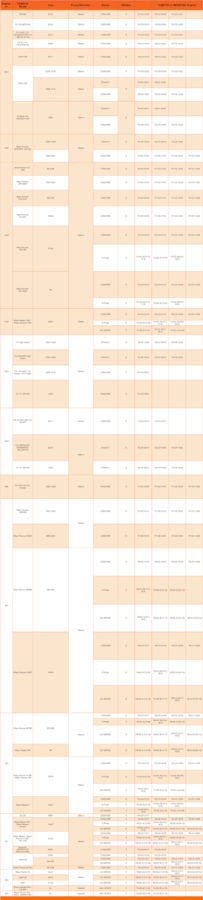

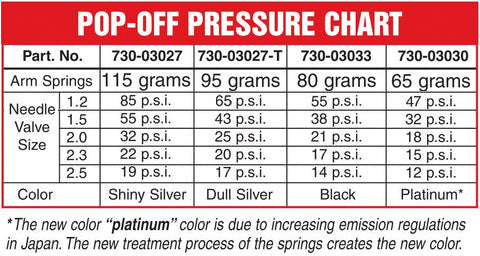

If you read the Mikuni tuning manual, it has a section where it shows what needles and seats and which springs will result in which pop-off pressure.

If you have the right parts, you will get the correct pop-off!

The spring will go by color.

Check your current needle and seat and the size will be stamped on it, small…

but it is there.

Proper procedure for pop-off.

1. Carb on bench, diaphragm cover and diaphragm removed, needle and seat facing up

2. Fuel “out” lines blocked, attach pop-off tester to fuel “in”.

3. Put a drop of WD40 (or similar generic light oil) onto needle and seat.

4. Pump tool to 10psi, and wait for 30 seconds (pressure should hold).

5. Gently pump until pressure rises and makes needle “pop”. (The pressure at pop is pop-off)

Now, we analyze the results. (It is important to understand this part).

Carb won’t hold pressure (won’t pump up to 10 and hold) – FAIL

Carb pops-off at a number close to the correct number (plus or minus 5 or 10 psi) – PASS

Carb won’t pop-off at all, or pops at 20psi+ over correct number – FAIL

If you failed, then you need to correct whatever is causing it to fail. It is not fixed by “adjusting” pop-off!

Common failure points:

Won’t hold pressure –

Square pump plates not sealed (poor gaskets or screws not tight), or plates warped

Needle and seat worn or damaged

Incorrect assembly of pivot arm and spring assembly

Won’t pop-off –

Needle and seat damaged (needle stuck in seat)

Incorrect springs, bent pivot arm